Picking strawberries may seem simple, but it has proven surprisingly difficult for even the most sophisticated of robots. Berries often ripen under a canopy of leaves, making it difficult for machines to detect and harvest them without damage.

Now, researchers at Washington State University think they have a solution: an AI-guided robot that combines soft silicone grippers and a fan that blows leaves aside before plucking the fruit.

During field trials in Huizhou, China, the machine successfully picked nearly three out of every four ripe strawberries using its fan system — a 16% improvement compared to trials without the fan. Each berry took the robot approximately 20 seconds to identify and harvest.

The team, which includes scientists in China, published their results this summer in the journal Computers and Electronics in Agriculture.

“Right now, [the technology] won’t totally replace manual labor,” said lead author Zixuan He, who is now a postdoctoral researcher at Aarhus University in Denmark. “But it could be a very promising supplement when you don’t have enough people in the field.”

Strawberry farming relies heavily on human labor, which is becoming increasingly scarce and expensive. For years, researchers have tried to automate the harvest, but most systems were tested in greenhouses or on table-top plants, where fruit hangs below the canopy and is easier to reach. The berries are more typically grown in open fields in the U.S., making hidden fruit a significant obstacle for robots.

The WSU robot combines several innovations:

- An AI-powered vision system trained with deep learning models teaches the machine to spot ripe berries and decide the best way to approach them.

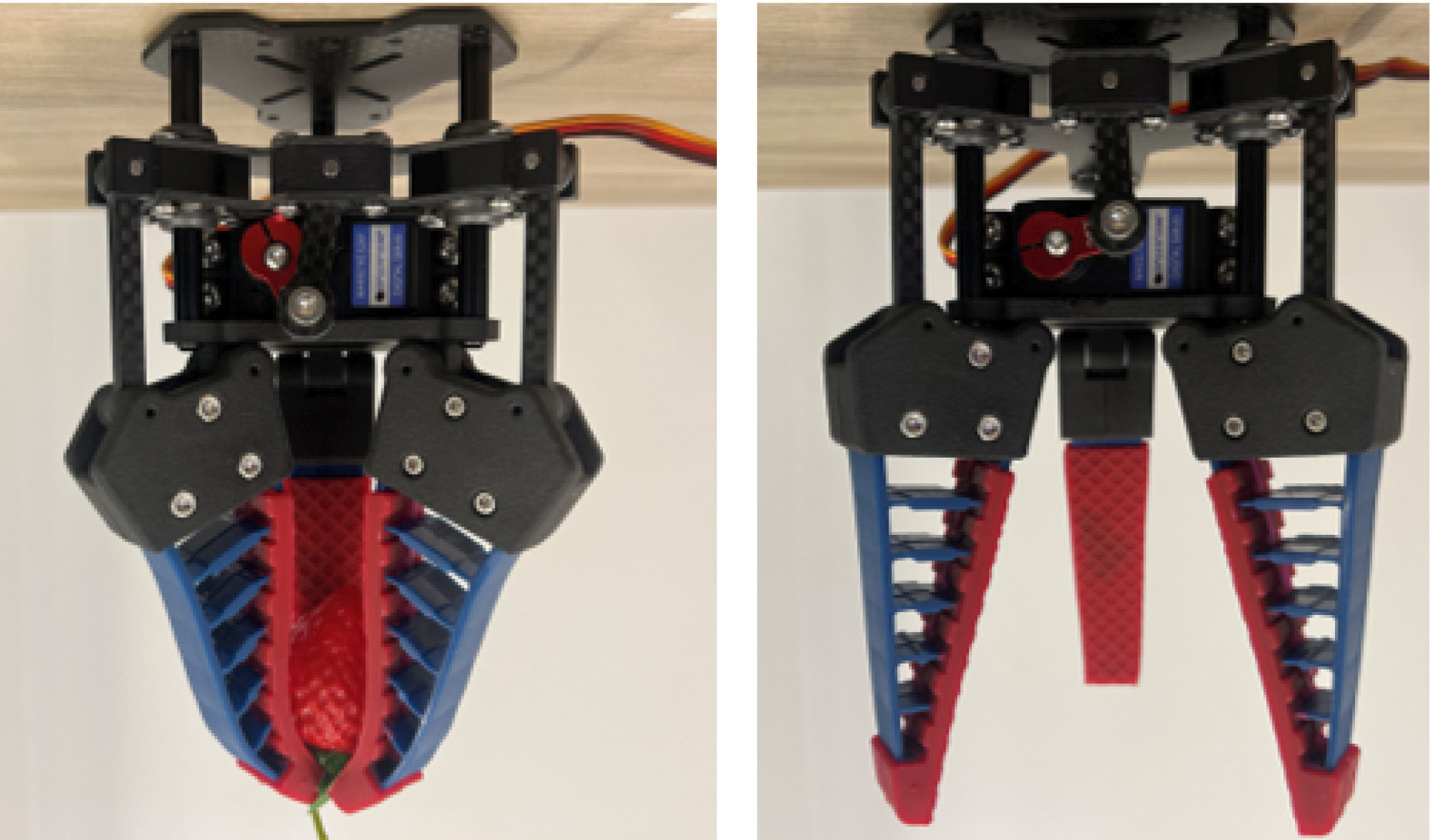

- A set of soft grippers to handles the fruit delicately.

- A fan system blows air through tubes near the grippers, parting leaves without harming the plants.

The WSU researchers’ study is the first to demonstrate field-scale robotic strawberry harvesting using airflow instead of mechanically moving the leaves. By integrating AI with new hardware, the team demonstrated that intelligent algorithms can enhance the effectiveness of robots in complex, unpredictable environments.

The system is slower than human pickers, but researchers estimate that deploying 10 robots with four arms each could harvest about 300,000 strawberries in roughly 43 hours. The scientists said a similar approach could be applied to other crops, such as grapes.

While still in research mode, the strawberry-picking robot is part of a wave of agtech innovation emerging from the Pacific Northwest. Last month, a British Columbia startup offering mushroom-picking robots raised $40 million. Seattle-area companies Carbon Robotics and Aigen have field robots that can identify and kill weeds with lasers or blades, while Idaho’s TerraClear developed machines that clear rocks from farmland.

Other authors of the paper titled “Improving picking efficiency under occlusion: Design, development, and field evaluation of an innovative robotic strawberry harvester” are Zibo Liu and Zhiyan Zhou of South China Agricultural University Guangzhou; Manoj Karkee, formerly of WSU and now a professor at Cornell University; and Qin Zhang, WSU professor emeritus.

Read the full article here